Researchers at Penn State University, USA, have created a new family of glass compositions, called Lionglass, that will help lower energy costs and extend tank lifetimes.

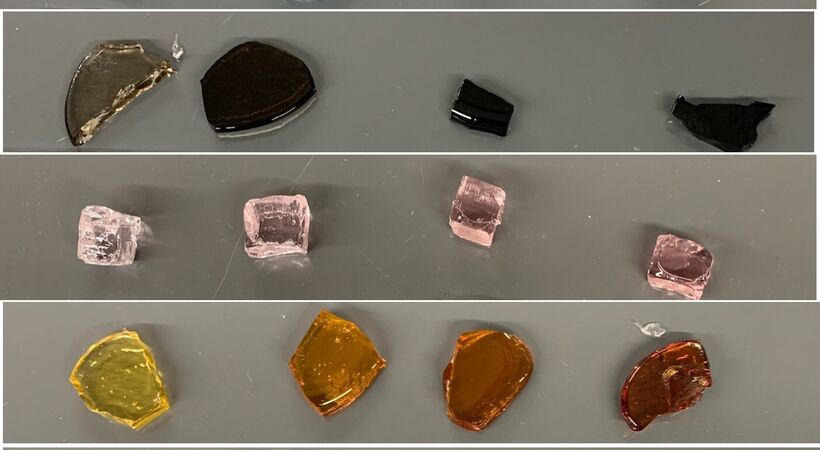

Lionglass is a new family of glass chemistry developed by a team of glass researchers at Penn State University.

LionGlass is meant to replace soda lime silicate glass — the common glass used on everyday items including windows, jars and drinking glasses.

The makers of LionGlass say it can help lead to more sustainable form of glass manufacturing.

Sustainable manufacturing

Soda lime silicate accounts for the vast majority of global glass production and is therefore responsible for the greatest carbon footprint of the glass industry as a whole.

There are two contributions to its carbon footprint: the high temperatures required for melting the glass and the release of carbon dioxide as carbonate batch materials (limestone and soda ash) decompose into oxides.

LionGlass addresses both of these sources of carbon dioxide emission by eliminating the use of carbonate batch materials and by lowering the melting temperature.

The lower temperatures will also help extend the lifetime of glass melting tanks.

Prof John C. Mauro of Penn State University said: “I believe this should be a win-win situation for everyone involved.

“Glass manufacturing partners will be at the forefront of a new glass innovation that will help lower energy costs, extend tank lifetimes, improve mechanical properties, and make a major move toward sustainable manufacturing.

“Consumers and society at large will benefit from the substantially lower carbon footprint of the glass industry.”